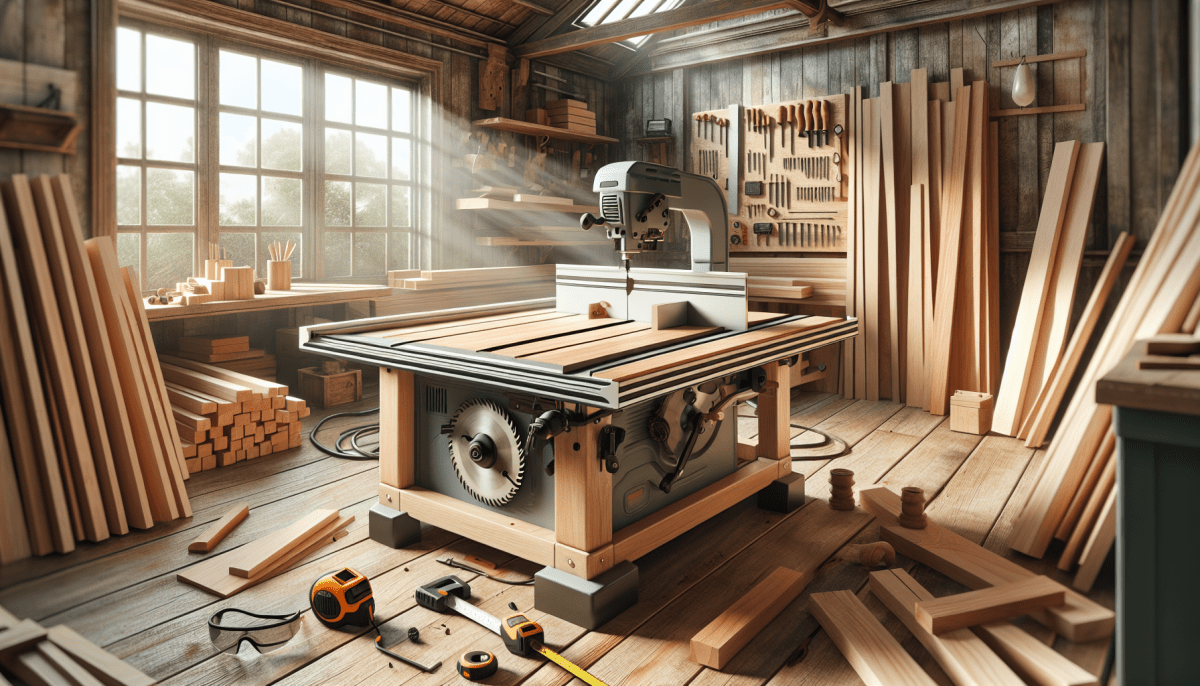

When working with a table saw, it's crucial to have a good grasp of its components and how they function together. At the heart of the table saw is the blade, which comes in various sizes and types, each tailored for specific cuts. Understanding the different blades available, such as rip blades for cutting along the grain and crosscut blades for cutting against it, allows woodworkers to choose the right tool for their projects.

Another key component is the fence. This device is essential for making accurate and consistent cuts. The fence runs parallel to the blade and adjusts to guide the wood as it's fed through the saw. A good fence is easy to adjust and locks securely in place, providing confidence that your measurements are precise. Investing time in setting up the fence correctly can significantly affect the quality of your work.

The table itself is another vital part. It supports the wood and provides a stable surface for cutting. A flat and smooth table will improve the quality of your cuts and reduce the risk of kickback. Many table saws come with extensions or auxilliary tables to support larger pieces of wood, enhancing both safety and precision as you work.

Finally, understanding the motor and its power rating is essential for determining the capabilities of your table saw. A powerful motor enables the saw to cut through hardwoods with ease, while a less powerful one may struggle. Knowing the specifications of your saw, including RPM and horsepower, helps you assess what types of materials you can work with and how efficiently you can complete your projects.

Essential Safety Tips for Table Saws

Table saws are powerful tools that can help you achieve precision in your woodworking projects. However, safety should always be your top priority when using this equipment. Here are some essential safety tips to keep in mind while working with table saws.

First and foremost, always wear appropriate personal protective equipment (PPE). Safety glasses are a must to protect your eyes from flying debris, while ear protection will help guard against the loud noise of the saw. Additionally, consider wearing a dust mask to avoid inhaling harmful wood dust. Proper footwear is also important; sturdy, closed-toe shoes can protect your feet in case of accidental drops.

Before starting your table saw, take the time to inspect the tool and your work area. Ensure that the blade is sharp and properly aligned. A dull blade can lead to kickback, which is a major safety hazard. Also, keep your workspace clean and free from clutter to avoid tripping hazards as you maneuver around your saw.

When operating the table saw, use push sticks or other aids to keep your hands at a safe distance from the blade. Your fingers should never come close to the cutting area. Always feed the wood into the blade firmly and at a steady pace; this helps prevent an unexpected kickback. Remember, a focused and calm approach will lead to better results and a safer experience.

Finally, ensure that any bystanders are at a safe distance from your work area. Keep children and pets away to prevent distractions and potential accidents. By following these essential safety tips, you can safely enjoy the versatility and creativity that table saws offer in your woodworking projects.

Techniques for Precision Cuts

When it comes to woodworking, achieving precision cuts with a table saw is essential for both aesthetics and the overall quality of your project. One of the first techniques that every woodworker should master is adjusting the fence. The fence is the guide that ensures your wood is cut straight and true. Before starting your cut, always measure the distance from the blade to the fence and make sure it's accurate. A small miscalculation can ruin your piece and waste valuable materials.

Another key technique is using the right blade for your project. Different types of blades serve different purposes. For instance, a rip blade is designed to cut with the grain of the wood, while a crosscut blade is optimized for cutting against the grain. Selecting the appropriate blade not only improves the quality of the cut but also reduces the chance of tear-out, leaving you with cleaner edges that require less sanding.

Moreover, utilizing push sticks and push blocks is vital for safety and precision. These tools help keep your hands at a safe distance from the blade while maintaining control over the workpiece. When guiding the wood through the saw, make sure to apply steady pressure with the push stick, letting the saw do the work. This technique minimizes the risk of kickback, which can occur if the wood binds against the blade.

Lastly, it’s important to maintain a consistent feed rate as you cut. Pushing the wood too quickly can lead to uneven cuts and splintering, while feeding it too slowly can overheat the blade and affect its integrity. Practice finding a balance that works for you, as mastery of this skill will significantly improve the quality of your cuts and overall woodworking experience.

Maintaining Your Table Saw Properly

Next, be sure to check and replace the saw blade when necessary. Dull blades can lead to inaccurate cuts, increased friction, and even strain the motor. Inspecting your blade for nicks and wear after several uses can help you identify when it needs replacing. Keep an extra blade on hand for different materials; using the right blade can make a world of difference in your finished projects.

Another important aspect of maintenance is regularly lubricating moving parts. The trunnion, elevation system, and tilt mechanism are essential components that benefit from occasional lubrication. Use a manufacturer-recommended lubricant to ensure optimal performance. Properly lubricated parts move smoothly and reduce the risk of wear and tear, ultimately extending the life of your table saw.

Finally, don’t forget to routinely inspect the electrical components of your table saw. A frayed cord or loose connection can pose serious hazards. Check for any signs of wear and tear, and if you notice anything unusual, it’s best to consult a professional for repairs. By being proactive and attentive to both the mechanical and electrical aspects of your table saw, you can keep it running smoothly and safely for all your woodworking needs.